60,000+

OXES

MANUFACTURED

PER DAY

OXES

MANUFACTURED

PER DAY

TONNES OF PAPER

CONVERTED

PER ANNUM

QUALIFIED

STAFF

SKILLED

WORKERS

• Imported 5 Ply & 3 Ply Automatic High Speed Corrugated Board Plant

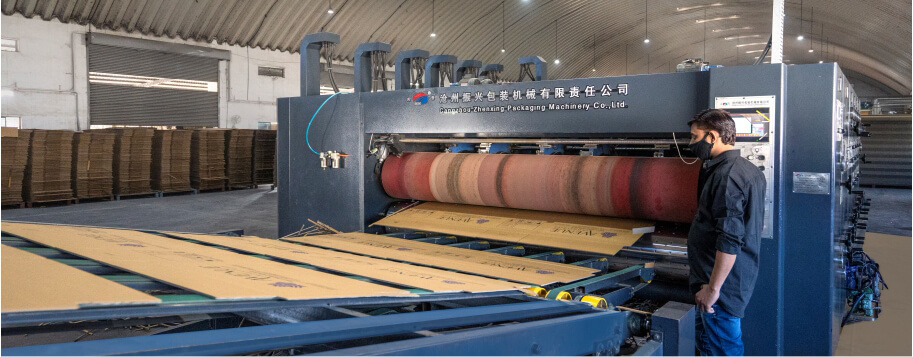

• Imported 4 Colour Flexo High-Speed Printing, Slotting and Die Cutting Machine

• Korean Made High Speed Automatic Folding, Gluing & Stitching Machine

• 2 Semi Automatic Folding & Stitching Machine

• Fully Automatic Glue Making Machine

• Fully Automatic Steam Boiler

• Best-in-Industry Well Equipped Q.C. Lab - Crush Resistance Tester, Bursting Strength Tester,

• Box Compression Strength Tester, Electronic GSM Tester, Cobb Value Tester, Moisture Meter, Puncture Resistance Tester

3 Tonnes capacity fully Automatic Steam Boiler ensures we’ve ample steam to continuously Produce High Quality Boards

Fully Automatic in-house Glue Kitchen ensures both Quality Consistency & Cost Effectiveness for Better Lamination

Well equipped QC Lab & dedicated technicians check quality of Raw Material, W-I-C & Finished Goods to ensure you get Nothing But the Best

Our 5 Ply & 3 Ply Automatic High Speed Corrugation Plant helps Meet Most Stringent Demands Urgently

4 colour Flexo High-Speed Printing, Slotting and Die Cutting Machine ensures Print Customisation without Production Delay

We’re equipped with High Speed Automatic Folding, Gluing & Stitching Machine for Quick Stitching & Gluing

Copyright © 2025 All rights reserved. Amigo Industries

Design by PROCOM