1,25,000+

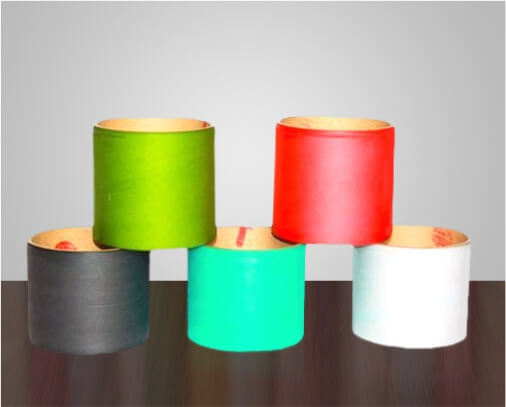

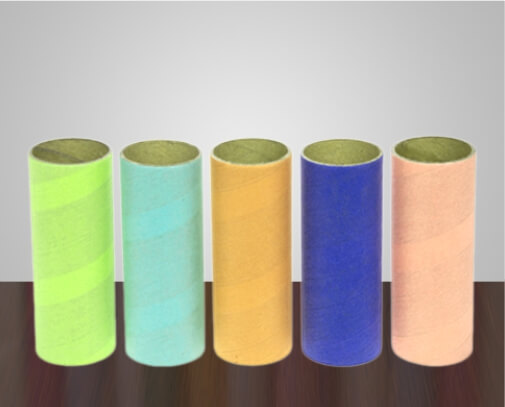

TUBES

PROCESSED DAILY

TUBES

PROCESSED DAILY

TONNES

YEARLY CONVERSION

QUALIFIED

STAFF

SKILLED

WORKERS

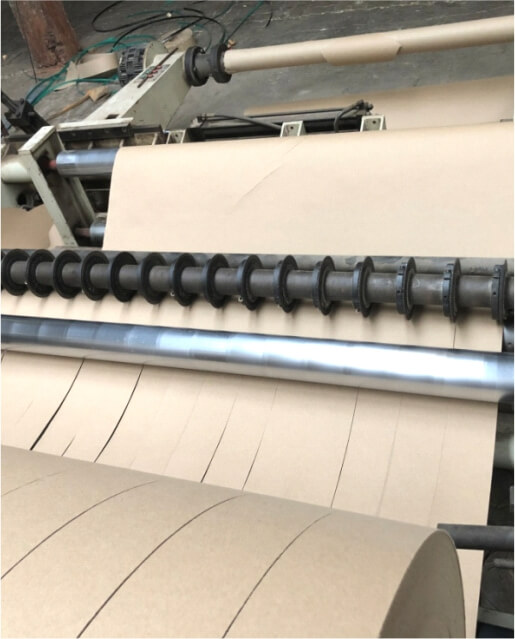

We slit our Paper Roll in-house, to maintain the accuracy of the size of Slitted Paper and to adjust the sizes with the changing season

Our high Speed Winding machines help us to ensure regular supply of long cores customised according to clients requirement

We have 6 Automated Cutting & Finishing lines that cut long Tubes & polish them efficiently to deliver the product on time

With years of Experience & Vendor Integrations, we always have ample raw material for any last minute order for timely delivery

We have 4 customised Drying Chambers dedicated to heat dry each Tube equally so as to avoid any variations in finished Paper Tubes

Our total plant area is spread across 60,000 sq.ft. which allow us to set the entire process line to optimise time and costs including storage

Copyright © 2025 All rights reserved. Amigo Industries

Design by PROCOM